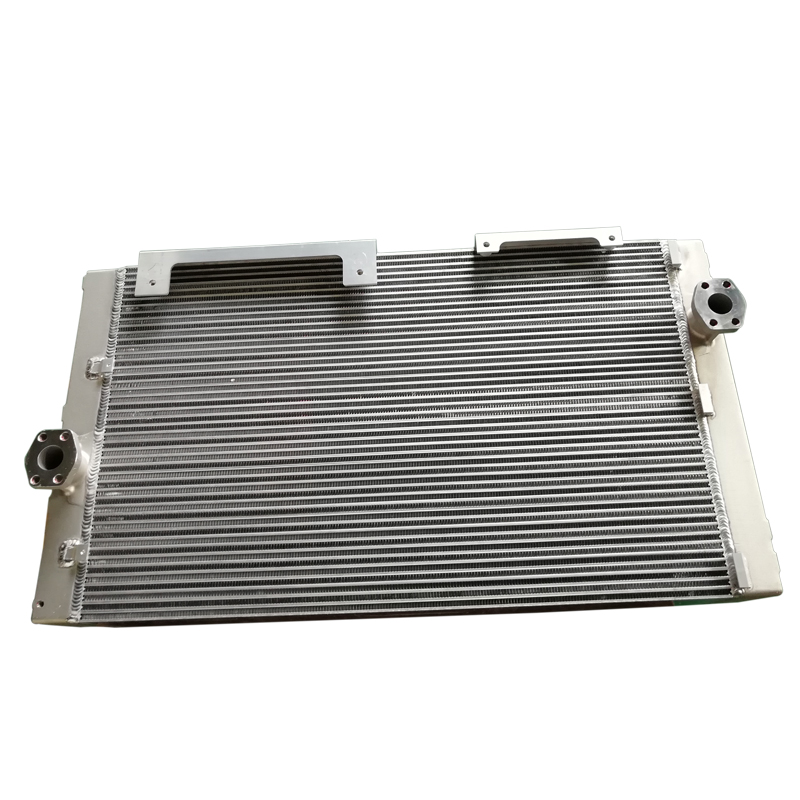

hydraulic oil coolers

Hydraulic oil coolers are devices used to regulate the temperature of hydraulic fluid in hydraulic systems. They help maintain optimal operating temperatures by dissipating heat generated during system operation. Hydraulic oil coolers typically consist of a series of tubes or fins that increase the surface area for heat transfer. As the hot hydraulic fluid flows through the cooler, it exchanges heat with the surrounding air or a separate cooling medium, such as water or another liquid. This process cools down the hydraulic fluid before it returns to the system, preventing overheating and ensuring efficient system performance.

Take the hydraulic system as an example, the equipment needs to maintain high pressure continuously when working, which will generate a lot of heat, and the oil temperature will rise after a long time of work. If the heat is not released in time, it will lead to the aging and damage of the sealing elements of the system, and the viscosity of the oil becomes lower with the rise of the oil temperature, and the oil pressure can not meet the requirements of the work. To ensure the safe and reliable operation of the equipment. The oil temperature must be controlled within the prescribed range. The main reason for the oil temperature rise of the lubrication system is different from that of the hydraulic system, but it is also necessary to control the oil temperature of the lubricating oil in the prescribed range. And the component that bears this responsibility is the oil cooler. Oil cooler is mainly used to cool hydraulic oil and lubricating oil; Oil cooler is widely used in plastic machinery, engineering machinery, mining machinery, automobile, steel, wind power, aerospace and other industries. There are many kinds of oil cooler, which can be divided into tube type and plate wing type. Compared with the tubular type oil cooler, the plate-fin type oil cooler can withstand higher pressure due to its structural characteristics. This makes the plate-fin type oil cooler widely used in wind power generation, hydraulic system, railway locomotive and other fields.

Soradiator is very focused on the development and development of plate fin type oil cooler. After more than ten years of exploration and development, formed a rigorous, efficient, high standard, high quality, flexible plate fin radiator production line. The engineers are constantly improving and perfecting the production process. From the flatness of the partition, fin structure, cleaning standards, assembly process, vacuum welding technology and time control, air tightness test, plug welding, have formed a set of very advanced and scientific production standards. The one-time pass rate of plate-fin core reaches more than 99%. At the same time, Soradiator manufacturers can adjust the fin structure, fin size and pressure resistance of the radiator according to the requirements of the equipment and the parameters provided by customers, so as to produce the most suitable products for customers to meet all the needs of customers for plate fin type radiator and oil cooler.